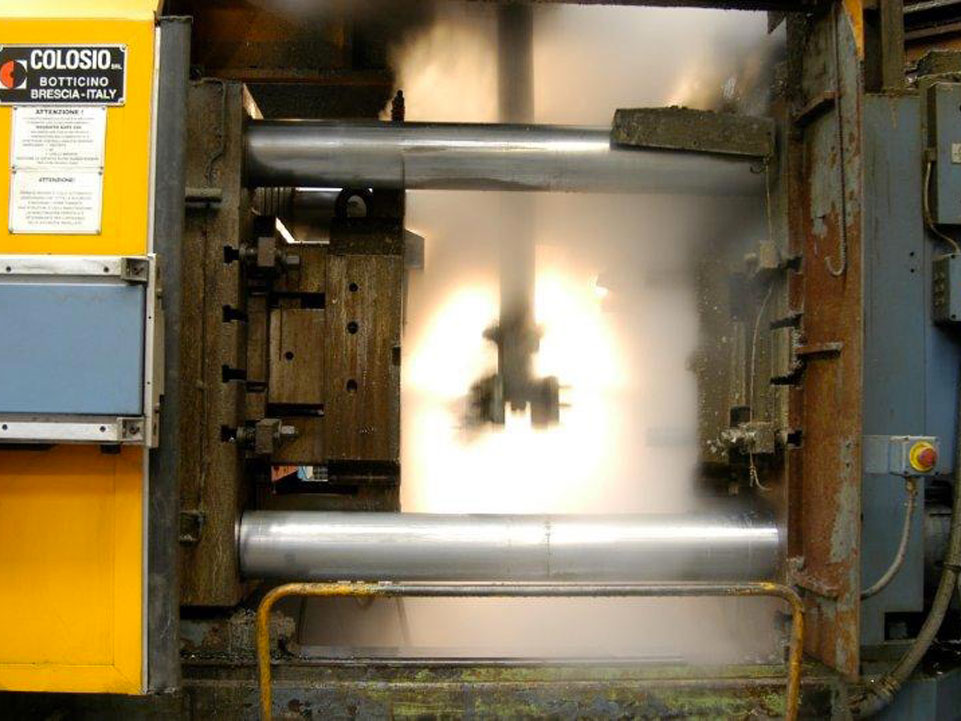

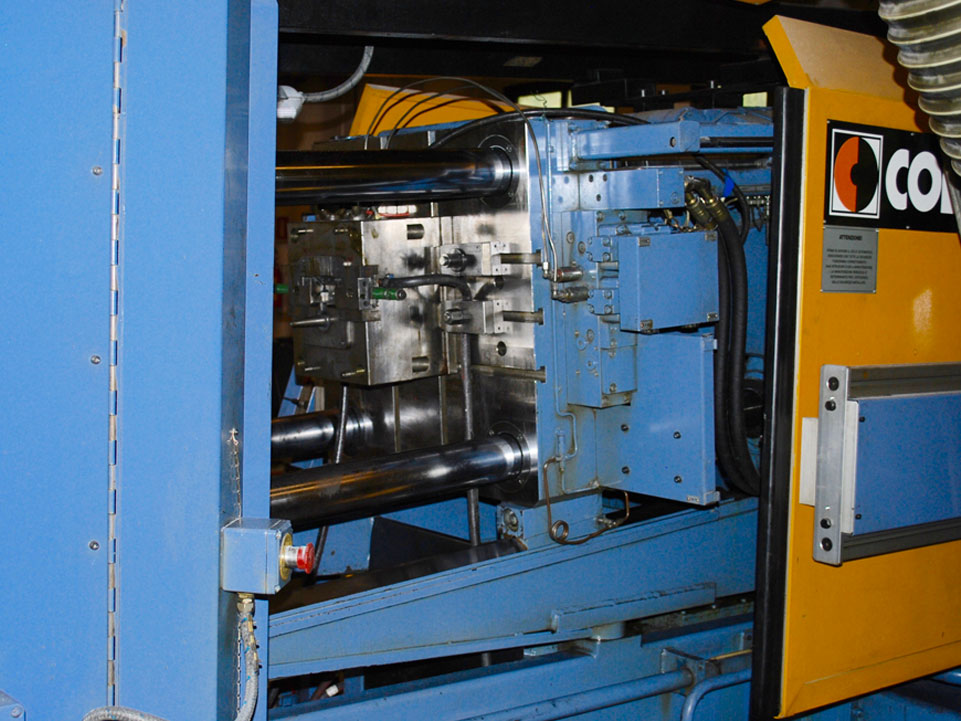

Alloy and aluminium die casting

The die casting process is carried out by some automatic or semi-automatic machines. In our production department, we employ completely computerized devices equipped with robots.

To produce castings, we have 14 die casting machines – 12 cold chamber and 2 hot chamber machines.

Spruing

Spruing is the operation that allows to cut the sprues – the waste metal left after casting – thanks to an approriate cutting equipment, which can be: manual, by means of plasma or shearing machine. This procedure enables a visual inspection on the manufactured material.